Sublimation: The Science Behind It

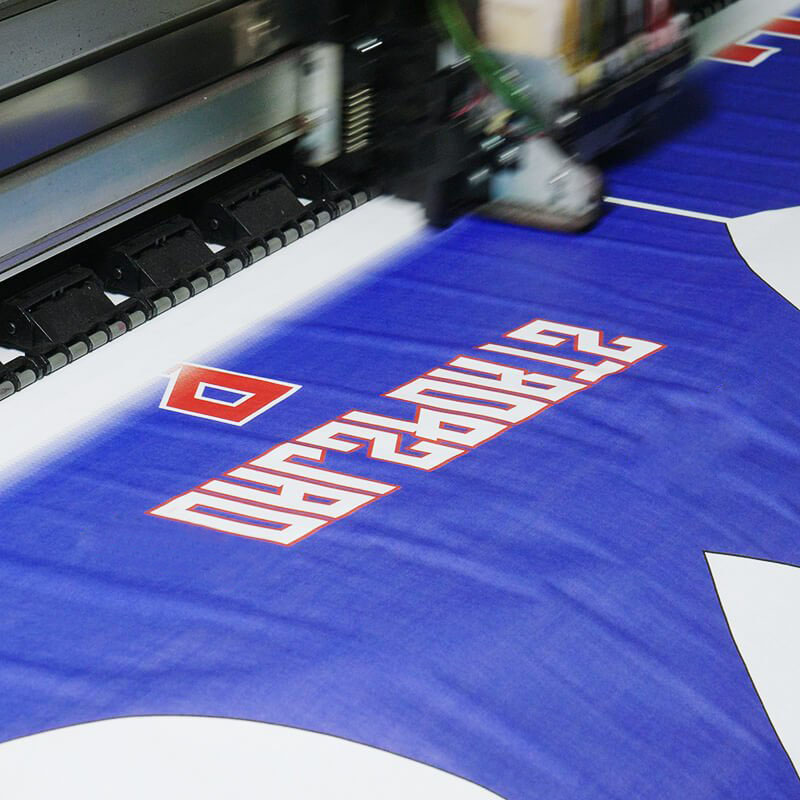

Nowadays, we are talking a lot about sublimation. What exactly is sublimation? It’s a really cool and versatile technique for decorating products. It allows you to create digital designs, digitize something hand-painted or take a digital photograph and permanently print it on a product. Mugs, phone cases, bags, t-shirts, notebooks, keychains…The list goes on and on. Simply print out your design using a dye sublimation printer and special transfer paper, then use a heat press to complete the transfer. Simply put, it is a printing method that uses ink and heat to transfer a design onto a material or fabric.

It was a game-changer in the apparel world as it enabled garments to be fully printed with seam-to-seam designs.

In sublimation, solids pass directly from the solid into the gas phase without becoming liquid in the medium. It is the process that transfers the desired motif. Transfer films or reverse transfer papers are printed in advance, then placed on the desired material and heated to 230°C for 30 to 60 seconds in a transfer press. When dyes are taken in this state, they are liquefied and fused to the fibers. Because the dyes are on the fabric after a successful transfer and not just glued on, you won’t see any residue – the motif is smooth and long-lasting.

Which materials can be printed with sublimation?

Not all materials work well for sublimation printing. In fact, some materials don’t work at all.

You must choose materials that will allow the ink gas to enter and lock into place during the transfer process. Remember – we’re looking for materials that will fuse with the ink on a molecular level.

By far the best materials for sublimation printing are polymers or objects coated with a polymer. The word polymer is a term used to describe a type of synthetic material made up of large molecules. It is a type of plastic whose chemical structure is particularly susceptible to sublimation printing. The most common polymer used for sublimation printing is polyester. Polyester is widely used and found in a variety of fabrics and products. When it comes to sublimation, polyester is the gold standard. Blanks made of 100% polyester can almost always be sublimated beautifully and easily. In fact, many different sublimation blanks are coated with a polyester polymer material, allowing for consistently high-quality results.

Which materials can’t be printed with sublimation?

As sublimation is always done on polyester, polymer or polymer coated items, 100% cotton materials are not suitable as natural fibers do not have pores that need to open up to take the image. Cotton can be sublimated, but the image will fade with a few washes. Make at least one fabric that is 50% polyester and 50% cotton.

The advantages and disadvantages

This technique has many ADVANTAGES:

it is one of the few methods that allow printing on rigid surfaces (cups, photo boards, plates, clocks, etc.). It is relatively easy and has a very short learning curve (quick learning curve). Offers an unlimited range of colors. With four-color ink (CMYK) you can get thousands of different colors. There is no additional cost when you add a new color to your design. That’s why it’s a fantastic option for printing photos. After sublimation, the print is integrated into the substrate and becomes part of it. Unlike transfer paper, the result does not feel, scratch, or lose color. Because it’s quick and easy, you can produce your orders on the same day. Today there are hundreds of items prepared for sublimation: mugs, plates, photo boards, wallets, flip-flops, clothing, decorative items, etc.

But it also has some DISADVANTAGES:

The fabric must be 100% polyester or at least 2/3 polyester. Only garments with a special polyester layer may be used for non-textile backing materials. or light-colored print areas. Black or dark surfaces cannot be sublimated. The item may lose color over the months due to exposure to UV rays if left in continuous direct sunlight. As with all inkjet printers, the printheads can become clogged if they are not used frequently. always on. It automatically cleans them daily. For each digital image transfer mark, the size of the print is limited by: The original resolution of the image, which defines the maximum size to which it can be enlarged. The dimensions of the lower platen of the press.

Do heat transfer and sublimation mean the same thing?

Sublimation uses a process where the ink becomes part of the fabric rather than adding a subcaste on top. This results in a transfer that’s unmatched in both continuity and feel. On the other hand, heat transfer paper adds a subcaste on top of the garment.

How Many Types Are There Of Heat Transfer?

Heat Transfer Printing

Heat transfer printing is a form of printing that uses heat to transfer images to a surface. Heat transfer printing (also known as thermal transfer printing, thermal printing, and thermal transfer printing) uses heat and pressure to apply custom designs to clothing or other items. to clothing or other objects. By applying heat and pressure to heat-treated materials, this printing process transfers custom designs or images to garments or other printed items. It is possible to decorate or print on various items including t-shirts, bags, caps, awards, plaques, and anything else that can withstand the high temperatures of the transfer using the heat transfer printing process. It is possible to print with different types of thermal transfer printing; However, currently, only two are widely used in the garment decoration industry. Examples of this type are vinyl (material-based transfer) and digital thermal transfer posting (ink-based transfer).

Vinyl Heat Transfer Printing

Vinyl heat transfer printing is a method of printing onto vinyl. This form of thermal transfer printing relies on the use of a body transfer material or film with a temperature-resistant adhesive backing such as B. Iron-On Vinyl (Heat Transfer Vinyl) to transfer custom designs onto garments. , unlike other types of heat transfer printing.

Digital Heat Transfer Printing

Digital thermal transfer printing is a type of printing that uses heat to transfer images from one surface to another (ink-based transfer). Aside from the use of heat, digital thermal transfer printing does not require any adhesive-backed material. Alternatively, use an inkjet or laser printer to print your designs onto unique heat transfer paper inlaid with clothing ink. You can press the shape onto your garment to transfer your designs to the fabric. This style of printing uses adhesives, but they are either applied directly to the surface of the transfer paper or already mixed with ink and activated by heat.

Conclusion

Garments can be decorated using sublimation and heat transfer printing techniques; Both printing technologies are affordable and advantageous. It is used to easily decorate fabrics with a few touches. Which method works best for you ultimately depends on your needs or the product you want to create, so the decision is entirely yours.

We hope that in this post we have shown you the differences between the two printing technologies and provided you with the necessary information to guide you in your journey into the world of garment decoration and printing.